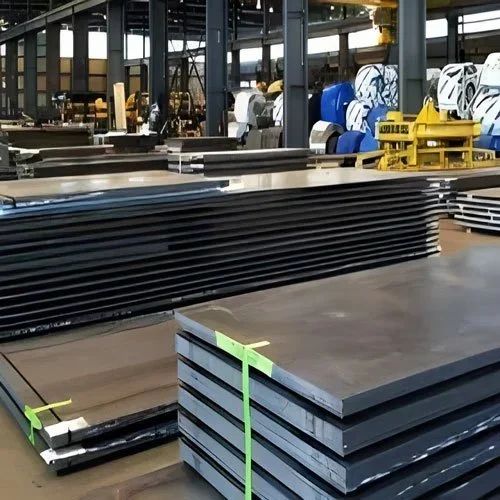

Boiler Steel Plate Manufacturers

What is Boiler Steel Plate Manufacturers

Boiler Steel Plate, also known as pressure vessel steel, is a type of carbon steel specifically engineered to withstand high-pressure environments, making it ideal for use in boilers, pressure vessels, and storage tanks. Its composition and mechanical properties are meticulously crafted to ensure optimal performance under extreme conditions.

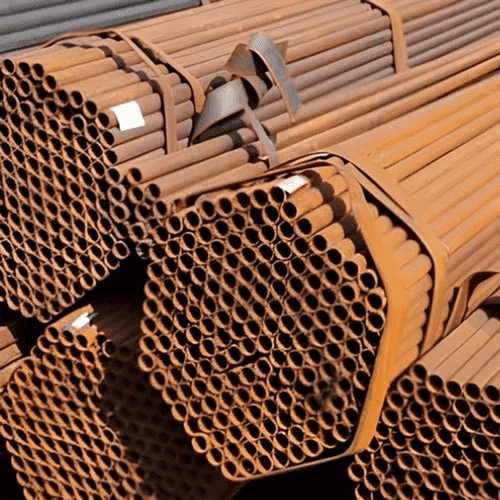

Importance of Boiler Steel Plate in Various Industries

The significance of boiler plate steel transcends multiple sectors, including energy, construction, transportation, and manufacturing. Its ability to withstand high temperatures and pressures makes it indispensable in the production of steam boilers, power generation equipment, and storage tanks for chemicals and gases.

Brief History of Boiler Steel Plate Manufacturers

The history of boiler Steel Plate dates back to the industrial revolution when the demand for reliable steam engines spurred advancements in metallurgy. Since then, the continuous refinement of manufacturing processes has led to the development of modern boiler plate steel with enhanced properties and performance.

Characteristics of Quality Boiler Steel Plate

1. Chemical Composition

Quality boiler Steel Plate is characterized by precise chemical composition, typically comprising low carbon content for weldability, along with alloying elements such as manganese, silicon, and nickel to impart strength and toughness.

2. Mechanical Properties

Superior mechanical properties, including high tensile strength, yield strength, and impact resistance, are hallmark features of boiler plate steel. These properties ensure structural integrity and reliability under varying operating conditions.

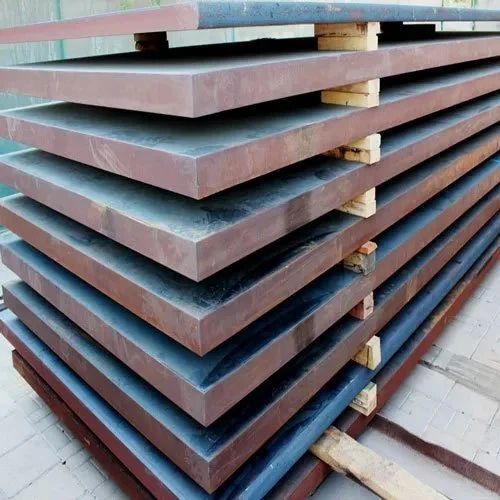

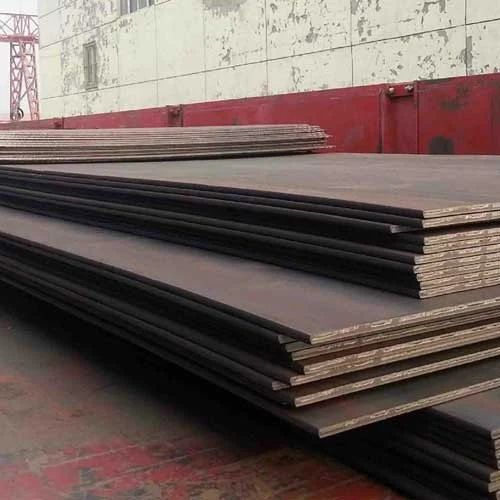

3. Thickness and Dimensions

Boiler plate steel is available in a range of thicknesses and dimensions to accommodate diverse applications. Manufacturers offer customization options to meet specific project requirements, ensuring optimal performance and cost-effectiveness.

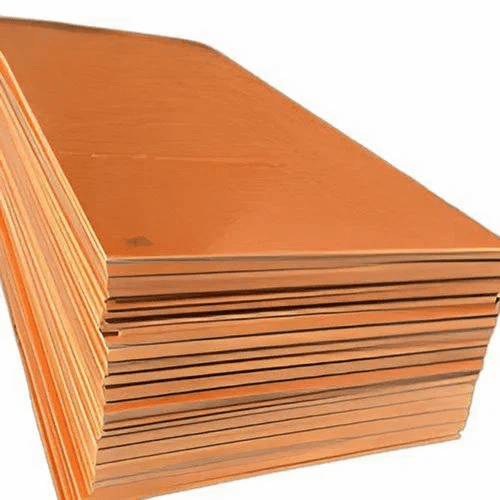

4. Corrosion Resistance

Effective corrosion resistance is essential for prolonged service life in harsh environments. Quality boiler plate steel undergoes corrosion-resistant treatments or alloying to mitigate the effects of corrosion, enhancing durability and longevit

1. Raw Material Selection

The manufacturing process begins with the meticulous selection of raw materials, including high-quality iron ore, coal, and alloying elements. The purity and consistency of raw materials significantly influence the properties and performance of the final product.

2. Steelmaking Process

Boiler plate steel is typically produced through primary steelmaking methods such as the blast furnace or electric arc furnace route. During steelmaking, the composition is carefully controlled, and impurities are removed to achieve the desired quality and properties.

3. Rolling and Forming

The molten metal is cast into slabs, which are subsequently hot-rolled into plates of the desired thickness. Rolling processes, including hot rolling and quenching, refine the microstructure of the steel, enhancing its mechanical properties and formability.

4. Heat Treatment

Heat treatment processes such as annealing, quenching, and tempering are employed to further optimize the mechanical properties of boiler plate steel. These processes impart specific hardness, strength, and toughness characteristics, ensuring suitability for intended applications.

STOCKISTS & TRADERS