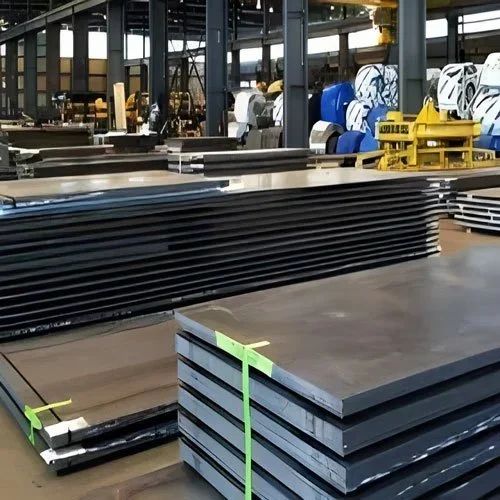

Boiler Steel Plate Grades

What is Boiler Steel Plate Grades

Boiler steel plate grades refer to specific classifications assigned to steel plates based on their chemical composition, mechanical properties, and intended applications. These grades are standardized by organizations such as ASTM, ASME, and EN, ensuring consistency and reliability in material performance.

Importance of Selecting the Right Grade

The selection of the appropriate boiler steel plate grade is crucial to ensure optimal performance, durability, and safety in high-pressure and high-temperature environments. Each grade possesses unique properties tailored to specific applications, making it imperative to match the grade with the operational requirements.

Characteristics and Properties of Boiler Steel Grade

- Composition: Primarily composed of carbon steel with moderate to high levels of manganese, phosphorus, sulfur, and silicon.

- Properties: Offers excellent tensile strength, yield strength, and notch toughness, making it suitable for moderate to lower temperature service.

- Applications: Widely used in the construction of pressure vessels for moderate to lower temperature applications in various industries, including power generation and oil refining.

- Tensile Strength: 70-90 ksi

- Yield Strength: 38 ksi

- Elongation: 17-21%

- Charpy V-Notch Impact Test: 20 ft-lb @ -20°F

2. ASTM A387 Grade 11

- Composition: Alloy steel plate comprising chromium and molybdenum, offering enhanced corrosion and oxidation resistance.

- Properties: Exhibits high-temperature strength and excellent creep resistance, making it ideal for elevated temperature service.

- Applications: Commonly employed in high-temperature applications such as power generation, petrochemical, and gas processing industries.

- Tensile Strength: 75-100 ksi

- Yield Strength: 45 ksi

- Elongation: 18%

- Creep Limit: 0.5% / 1000 hours @ 600°F

3. ASTM A285 Grade C

- Composition: Carbon steel plate with low to intermediate tensile strength and moderate to low carbon content.

- Properties: Suitable for moderate pressure vessel service, offering good weldability and formability.

- Applications: Used in the construction of boilers and pressure vessels for moderate-pressure applications in various industries.

- Tensile Strength: 55-75 ksi

- Yield Strength: 30 ksi

- Elongation: 23%

- Charpy V-Notch Impact Test: 27 J @ -20°C

- Composition: Heat-treated carbon-manganese-silicon steel plate with high tensile strength and impact toughness.

- Properties: Designed for elevated temperature service, offering excellent strength and resilience at higher temperatures.

- Applications: Primarily utilized in the construction of pressure vessels and storage tanks for high-temperature applications in the oil, gas, and petrochemical industries.

- Tensile Strength: 70-90 ksi

- Yield Strength: 50 ksi

- Elongation: 22%

- Charpy V-Notch Impact Test: 75 ft-lb @ -20°F

Applications of Different Boiler Steel Plate Grades

A. Power Generation

Boiler steel plates are extensively utilized in power generation plants for the construction of boilers, steam turbines, and pressure vessels. Grades such as ASTM A516 Grade 70 and ASTM A387 Grade 11 Class 2 are commonly employed due to their high-temperature strength and corrosion resistance.

B. Oil and Gas Industry

In the oil and gas industry, boiler steel plates are essential for the fabrication of pressure vessels, storage tanks, and heat exchangers used in refining, processing, and transportation operations. Grades like ASTM A537 Class 1 provide optimal performance in high-pressure and corrosive environments.

C. Petrochemical Plants

Petrochemical plants rely on boiler steel plates for the construction of reactors, distillation columns, and storage tanks handling corrosive chemicals and gases. Grades such as ASTM A285 Grade C offer excellent weldability and formability, facilitating the fabrication of complex structures.

D. Aerospace and Defense

In aerospace and defense applications, boiler steel plates find use in the fabrication of pressure vessels, rocket engine components, and aircraft structures subjected to high-stress conditions. High-strength grades like ASTM A537 Class 1 ensure structural integrity and reliability in extreme environments.

STOCKISTS & TRADERS